Manual compactors are essential tools for compressing waste or materials, enhancing efficiency and sustainability. They reduce space, lower disposal costs, and promote eco-friendly practices across industries.

1.1 What is a Manual Compactor?

A manual compactor is a device or tool used to compress materials, such as waste, soil, or gravel, by applying force manually. It operates without electricity, relying on human effort or simple mechanisms like levers or pedals. These compactors are designed to reduce the volume of materials, making them easier to handle, transport, or store. They are commonly used in construction, agriculture, and waste management to enhance efficiency and reduce space. Manual compactors are cost-effective, environmentally friendly, and ideal for small-scale applications where automated systems are unnecessary. Their simplicity makes them accessible for various industries and domestic use.

1.2 Importance of Manual Compactors in Waste Management

Manual compactors play a crucial role in waste management by reducing waste volume, enhancing efficiency, and lowering disposal costs. They minimize the space occupied by waste materials, making transportation and storage more cost-effective. By compacting waste, they reduce the frequency of waste collections and the need for large disposal containers. Manual compactors also promote sustainability by reducing landfill requirements and encouraging recycling. Their simplicity and energy efficiency make them an eco-friendly solution for small-scale operations. Additionally, they are cost-effective alternatives to automated systems, making them accessible for businesses and households aiming to manage waste responsibly and contribute to environmental conservation.

1.3 Brief History and Evolution of Manual Compactors

Manual compactors have evolved significantly over the years, originating from simple tools used in ancient construction and agriculture. Early versions involved rudimentary levers and presses for compacting soil and waste. The Industrial Revolution brought mechanized systems, but manual compactors remained essential for small-scale applications. In the mid-20th century, their design improved with the introduction of hydraulic and lever-based systems, enhancing efficiency. Modern manual compactors incorporate lightweight materials, ergonomic designs, and adjustable mechanisms, catering to diverse industries. Their evolution reflects a balance between simplicity and innovation, ensuring they remain practical for waste management, construction, and landscaping. This adaptability has secured their relevance in various sectors.

Types of Manual Compactors

Manual compactors are categorized into portable, stationary, and specialized models, each designed for specific applications in waste management, construction, and industry, ensuring optimal efficiency and usability;

2.1 Portable Manual Compactors

Portable manual compactors are lightweight, compact, and easy to transport, making them ideal for small-scale operations. They are designed for ease of use in confined spaces, such as construction sites, small businesses, or households. These compactors typically feature durable materials like steel and simple mechanisms, often operated by levers or hand-powered systems. Their portability allows for versatility in applications, from temporary job sites to outdoor projects. With no need for electricity, they are cost-effective and environmentally friendly. Portable manual compactors are perfect for reducing waste volume efficiently in settings where larger equipment is impractical, ensuring convenience and adaptability for various user needs.

2.2 Stationary Manual Compactors

Stationary manual compactors are robust, non-portable units designed for heavy-duty use in fixed locations. They are ideal for high-volume waste management in industrial settings, such as factories, large construction sites, or municipal facilities. These compactors typically feature a sturdy frame and powerful compaction mechanisms, often requiring minimal effort to operate. Their fixed installation ensures stability and consistent performance, making them suitable for continuous use. Stationary models often include features like large compaction chambers and durable materials, ensuring long-term reliability. They are commonly used for compacting industrial waste, construction debris, and bulky materials, reducing waste volume and disposal costs effectively while maintaining efficiency.

2.3 Specialized Manual Compactors for Specific Industries

Specialized manual compactors are tailored to meet the unique needs of specific industries, offering customized solutions for diverse materials and environments. For instance, agricultural compactors are designed to handle organic waste and bulky farm materials, while construction models focus on dense debris like gravel and concrete. Hospitality and healthcare industries benefit from compactors with odor-control and sanitary features for food or medical waste; Additionally, compactors for landscaping efficiently compress soil and greenery, while industrial models are built to withstand heavy-duty applications. These specialized units ensure optimal performance, safety, and efficiency for their intended use cases, making them indispensable in their respective sectors.

Design and Construction of Manual Compactors

Manual compactors are built with durable materials like steel, featuring robust frames and ergonomic handles. Their design includes safety mechanisms, ensuring efficient and secure operation.

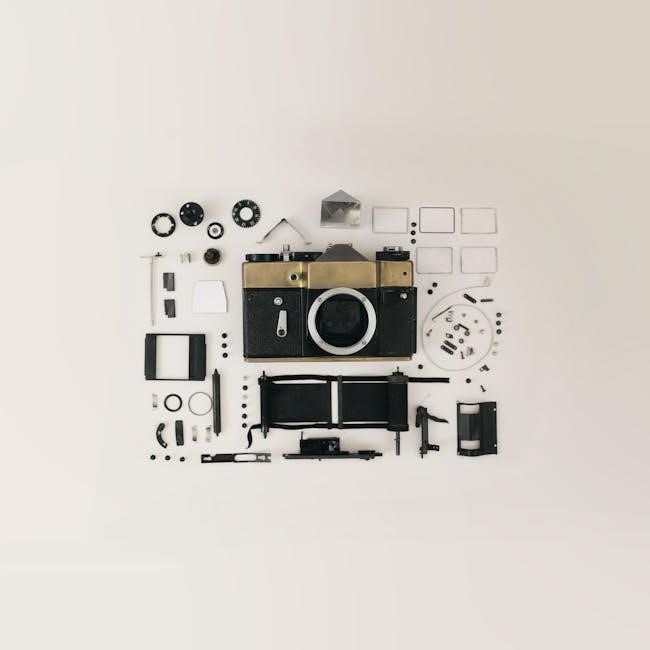

3.1 Key Components of a Manual Compactor

A manual compactor consists of a sturdy frame, a compaction plate, and a handle. The frame provides structural integrity, while the plate compresses materials. The handle enables manual operation, often with a leverage system to amplify force. Safety features like locking mechanisms and ergonomic grips are common. Some models include wheels for portability. These components work together to ensure efficient and safe compaction of waste or materials, making manual compactors versatile tools for various applications.

3.2 Materials Used in Manufacturing

Manual compactors are typically constructed from durable materials to ensure longevity and effectiveness. Steel and wrought iron are common choices for frames and compaction plates due to their strength and resistance to wear. Handles are often made from high-strength plastics or rubber for better grip and ergonomics. Some models may incorporate lightweight yet robust alloys to balance portability and durability. The use of weather-resistant coatings or paints is also prevalent to protect against corrosion, especially for outdoor applications. These materials ensure that manual compactors can withstand rigorous use across various environments and industries while maintaining optimal performance and safety standards.

3.3 Compact Mechanisms and Leverage Systems

Manual compactors utilize simple yet effective mechanisms to compress materials. The primary system involves a lever or handle that, when operated, applies significant force to a compacting plate or ram. This mechanism relies on leverage to amplify the user’s strength, enabling efficient compression of waste or soil. Many models feature gears or fulcrum points to enhance force multiplication, reducing the effort required; The compacting action is typically achieved through a downward motion, with some designs incorporating springs or dampers to ease the return stroke. These systems are designed for durability, ensuring consistent performance across various applications, from construction sites to agricultural settings, while maintaining user safety and efficiency.

Applications of Manual Compactors

Manual compactors are versatile tools used in waste management, construction, agriculture, and domestic settings. They efficiently compress materials, reducing space and enhancing operational efficiency across various industries.

4.1 Waste Management and Recycling

Manual compactors play a crucial role in waste management and recycling by efficiently compressing materials, reducing waste volume, and optimizing storage space. They are widely used in recycling facilities to process materials like cardboard, plastics, and metals, ensuring easier transportation and storage. In municipal operations, these compactors help manage mixed solid waste, separating recyclables from non-recyclables to minimize landfill use. Additionally, manual compactors are effective in household settings, allowing individuals to compact waste and recyclables, promoting eco-friendly practices. Their ability to reduce waste bulk significantly lowers disposal costs and environmental impact, making them indispensable tools in sustainable waste management systems.

4.2 Construction and Building Sites

Manual compactors are invaluable in construction and building sites for soil and material compaction. They are used to prepare stable bases for foundations, roads, and other structures, ensuring durability and safety. By reducing air pockets and settling, compactors enhance the structural integrity of the ground. Their portability and ease of use make them ideal for smaller or hard-to-reach areas. Regular use of manual compactors on construction sites saves time and costs by preventing future repairs and ensuring even surface distribution. They are essential tools for contractors and builders, contributing to efficient and high-quality project outcomes in various construction environments.

4.3 Agricultural and Landscaping Uses

Manual compactors play a crucial role in agricultural and landscaping applications by stabilizing soil and materials. They are used to prepare seedbeds, compact soil for plantings, and create firm pathways, reducing erosion risks. In landscaping, they help in laying pavers, gravel, and sod, ensuring even surfaces. Farmers use them to compact barn floors and silage pits, improving hygiene and storage efficiency. Their portability and ease of use make them ideal for small-scale farming and gardening projects. Regular compaction aids in root growth and water retention, promoting healthier crops. Manual compactors are eco-friendly and cost-effective tools for sustainable land management and agricultural productivity.

4.4 Domestic and Small-Scale Applications

Manual compactors are ideal for domestic environments, assisting homeowners in managing waste efficiently. They are particularly useful in small spaces, such as kitchens or gardens, where they help reduce waste volume and promote neatness. These compactors are portable, easy to use, and require minimal maintenance, making them suitable for small-scale applications. By compressing waste, they minimize landfill contributions and support eco-friendly practices. Their compact design allows for easy storage, and they are cost-effective alternatives to larger, more expensive models. Manual compactors effectively handle various types of waste, including food scraps and recyclables, making them indispensable for eco-conscious households aiming to reduce their environmental footprint.

Operation and Maintenance

Proper operation and regular maintenance ensure efficiency, longevity, and safety. Follow guidelines for use, clean regularly, and lubricate moving parts to prevent wear and tear effectively.

5.1 Step-by-Step Guide to Using a Manual Compactor

Begin by preparing the site, ensuring the surface is clear of debris. Position the compactor firmly on the material to be compressed. Activate the mechanism, applying consistent force to compact the waste or soil in even layers. Repeat the process, overlapping strokes to achieve uniform density. After compacting, inspect the surface for any soft spots or uneven areas. Regularly clean and lubricate moving parts to maintain efficiency. Follow safety guidelines to avoid accidents and ensure optimal performance. Always refer to the manufacturer’s manual for specific instructions tailored to your model.

5.2 Safety Precautions and Best Practices

Always wear protective gear, including gloves and safety glasses, when operating a manual compactor. Ensure the area is clear of obstacles and bystanders. Secure loose clothing and avoid wearing jewelry that could get caught in moving parts. Follow the manufacturer’s guidelines for load limits and operation techniques. Keep children and unauthorized individuals away from the equipment. Regularly inspect the compactor for wear or damage, addressing issues promptly. Use proper lifting techniques to avoid injury. Maintain a firm grip on handles and operate the compactor on stable, even ground. Never leave the compactor unattended while in use, and ensure proper training for all operators.

5.3 Regular Maintenance and Upkeep

Regular maintenance is crucial to ensure optimal performance and longevity of manual compactors. Lubricate moving parts periodically to prevent rust and friction. Inspect hinges, handles, and compacting plates for wear or damage, replacing them as needed. Clean the compactor after each use to remove debris and prevent contamination. Check for loose bolts or screws and tighten them promptly. Store the compactor in a dry, protected area to avoid environmental damage. Refer to the manufacturer’s maintenance schedule for specific recommendations. Addressing issues early prevents major repairs and ensures consistent efficiency in waste management tasks.

5.4 Troubleshooting Common Issues

Common issues with manual compactors often involve jamming, reduced compaction force, or mechanical malfunctions. If materials get stuck, stop immediately and clear the blockage. Lubricate hinges and moving parts if the compactor feels stiff. Check for worn or damaged components like seals or plates and replace them as needed. If the compactor isn’t compressing effectively, ensure proper alignment and leverage use. Overloading is a frequent problem; adhere to weight and size limits. Regularly inspect belts and chains for wear. Refer to the user manual for specific troubleshooting guides tailored to your model. Addressing these issues promptly ensures smooth operation and extends the device’s lifespan.

Factors to Consider When Choosing a Manual Compactor

Consider size, weight, portability, budget, and environmental impact. Choose models that match your waste volume, mobility needs, and sustainability goals while staying within budget constraints.

6.1 Size and Capacity Requirements

Choosing the right size and capacity is crucial for effective waste management. Assess the volume of waste generated and available space for the compactor. Larger capacities reduce emptying frequency but may be impractical in tight spaces. Compactness and maneuverability are key for portable models. Consider the type of waste— denser materials require higher compaction force. Ensure the compactor’s dimensions fit your workspace. For construction or agricultural settings, heavier-duty models with larger capacities are essential. Evaluate daily waste output to avoid under-sizing or over-sizing the unit. Proper sizing optimizes efficiency, reduces costs, and ensures smooth operation. Always measure your space and waste needs accurately.

6.2 Weight and Portability Needs

Weight and portability are critical factors for manual compactors, especially in mobile applications. Lighter models are easier to transport, making them ideal for construction sites or temporary setups. Portable compactors often feature compact designs and handles for easy maneuverability. For stationary use, heavier units may be preferred for stability. Assessing the frequency of relocation helps determine the optimal weight. Durable materials like steel ensure longevity without compromising mobility. Compact designs also save space, enhancing versatility. Balancing weight and portability ensures efficiency and ease of use across various settings, from small businesses to large-scale projects. Proper weight distribution enhances safety during transportation and operation.

6.3 Cost and Budget Constraints

When selecting a manual compactor, cost and budget constraints play a significant role. Manual compactors vary in price, with portable models generally being more affordable than stationary or specialized units. Budget considerations should include initial purchase costs, maintenance, and potential repair expenses. Affordable options may lack advanced features, while high-end models offer durability and efficiency. Evaluating long-term savings, such as reduced waste disposal costs, can justify higher initial investments. Balancing budget limits with functionality ensures a practical choice. It’s essential to compare models and brands to find the best value within your financial means, avoiding overspending or compromising on essential features.

6.4 Environmental and Efficiency Considerations

Manual compactors offer significant environmental benefits by reducing waste volume, minimizing landfill space, and lowering carbon emissions. They are energy-efficient alternatives to automatic compactors, requiring no electricity and reducing reliance on fossil fuels. Their compact designs promote sustainable waste management by enabling better recycling and disposal practices. Efficiency is maximized through effective compaction, which reduces the frequency of waste collection and transportation needs. Eco-conscious users often prefer manual compactors for their low environmental impact and cost-effectiveness. By prioritizing efficiency and sustainability, manual compactors align with green initiatives and support long-term environmental goals, making them a practical choice for eco-friendly operations across various industries and applications.

Environmental Impact of Manual Compactors

Manual compactors significantly reduce waste volume, lowering landfill needs and emissions. They promote recycling efficiency and support sustainable practices, making them eco-friendly solutions for waste management.

7.1 Waste Reduction and Compaction Efficiency

Manual compactors excel at reducing waste volume through efficient compaction, minimizing landfill space and disposal costs. By compressing materials tightly, they prevent waste from decomposing slowly, reducing methane emissions. Their compact design enables consistent pressure application, ensuring high-density compaction. This efficiency is particularly beneficial in construction and agricultural settings, where large volumes of waste are generated. Regular use of manual compactors can significantly lower environmental impact by reducing the frequency of waste collection and transportation. Their simplicity and effectiveness make them a vital tool for sustainable waste management practices, contributing to a greener and more resource-efficient future.

7.2 Energy Efficiency Compared to Automatic Compactors

Manual compactors are highly energy-efficient compared to automatic models, as they operate without electricity or fuel. This eliminates the need for power consumption during operation, significantly lowering energy costs. Unlike automatic compactors, which rely on motors and hydraulics, manual compactors use human effort or simple mechanical leverage. This reduces their carbon footprint and makes them environmentally friendly. Additionally, manual compactors require minimal maintenance, further reducing their overall energy demand. Their simplicity and lack of reliance on fossil fuels make them a sustainable choice for waste management, especially in small-scale or remote applications where energy availability is limited.

7.3 Contribution to Sustainable Waste Management

Manual compactors play a crucial role in sustainable waste management by reducing waste volume and minimizing landfill use. They enable efficient compression of materials, making recycling and proper disposal easier. By decreasing the need for frequent waste collections, they lower carbon emissions from transportation. Their energy efficiency and minimal environmental impact align with eco-friendly practices. Additionally, manual compactors promote the segregation and processing of recyclables, enhancing waste-to-resource conversion. This approach supports circular economy principles and helps communities achieve long-term sustainability goals. Their simplicity and effectiveness make them a vital tool in modern waste management strategies aimed at preserving the environment for future generations.

Advanced Features in Modern Manual Compactors

Modern manual compactors feature adjustable compaction force, interchangeable plates, and hybrid models, enhancing efficiency, customization, and sustainability for various applications.

8.1 Adjustable Compaction Force

Adjustable compaction force in modern manual compactors allows users to customize pressure based on material type and density, optimizing efficiency and reducing damage to equipment. This feature, often controlled via levers or dials, enables precise control, ensuring optimal compaction without excessive force. Industries like construction and recycling benefit significantly, as it adapts to varying waste or material requirements. Adjustable force also reduces operator fatigue by tailoring effort to specific tasks, enhancing overall productivity. Advanced models may include presets for common materials, streamlining operations and reducing setup time. This versatility makes manual compactors more adaptable to diverse applications, improving both performance and user satisfaction.

8.2 Interchangeable Compacting Plates

Interchangeable compacting plates offer versatility by allowing users to switch between different plate designs tailored for specific materials or tasks. This feature enhances efficiency and adaptability, enabling manual compactors to handle a wide range of applications. Plates can be swapped quickly, often without tools, reducing downtime and increasing productivity. Industries benefit as they can use the same compactor for various materials, from fine soils to heavy debris. This adaptability makes manual compactors cost-effective and practical for diverse projects, ensuring optimal performance across different scenarios. The ability to customize plates for specific needs further extends the utility of these compactors in both professional and domestic settings.

8.3 Hybrid Models with Additional Functionality

Hybrid manual compactors combine traditional manual operation with advanced features, offering enhanced versatility and performance. These models often integrate smart technology, such as sensors or adjustable settings, to optimize compaction efficiency. Some hybrids include dual-mode functionality, allowing users to switch between manual and powered operation, reducing physical effort. Additional features like data tracking or automated force adjustment further improve usability. Hybrid models are ideal for environments requiring flexibility, as they cater to both small-scale and large-volume needs. Their innovative design bridges the gap between manual and automatic compactors, making them a cost-effective and eco-friendly solution for modern waste management and material handling challenges.

Case Studies and Real-World Applications

Manual compactors have proven effective in construction projects, reducing waste volume and enhancing site efficiency. Municipalities worldwide use them for sustainable waste management, while agricultural settings benefit from their versatility in compacting organic materials.

9.1 Successful Implementation in Construction Projects

Manual compactors play a crucial role in construction projects by efficiently compressing materials and waste, reducing storage space and disposal costs. They are particularly useful for compacting soil to create stable bases for foundations and roads, ensuring structural integrity. In addition, these compactors help manage demolition debris, allowing for easier handling and recycling of materials. Their portability and ease of use make them ideal for various construction sites, enhancing overall project efficiency. By minimizing waste volume, manual compactors contribute to cost savings and environmental sustainability, making them an essential tool in modern construction practices that prioritize efficiency and eco-friendliness.

9;2 Effective Use in Municipal Waste Management

Manual compactors are widely utilized in municipal waste management to reduce waste volume, lowering disposal costs and enhancing operational efficiency. They are particularly effective in transfer stations, where they compact mixed municipal solid waste (MSW) before transportation to landfills. These compactors are also used in recycling facilities to process specific materials, such as cardboard, ensuring optimal use of space and resources. Their portability and ease of operation make them ideal for smaller-scale applications, including community recycling centers. By minimizing waste bulk, manual compactors contribute to sustainable waste management practices, reducing landfill dependency and promoting eco-friendly solutions for urban and rural municipalities alike;

9.3 Innovative Applications in Agricultural Settings

Manual compactors are increasingly being used in agricultural settings to enhance soil preparation and waste management. Farmers utilize these tools to compact soil for optimal crop growth, ensuring stable ground conditions. Additionally, manual compactors are employed for recycling organic waste, such as compost and crop residues, reducing waste volume and odors. They are also used to prepare fields for irrigation systems and drainage solutions. In livestock farming, compactors help manage manure efficiently, reducing environmental impact. Their portability and versatility make them ideal for small-scale and organic farming operations, contributing to sustainable land management and resource optimization in rural areas. This innovative application supports eco-friendly farming practices.

Future Trends in Manual Compactor Technology

Emerging trends include innovative designs, smart technology integration, and eco-friendly materials. These advancements aim to enhance efficiency, sustainability, and user experience in waste management and material compaction.

10.1 Emerging Innovations in Design

Emerging innovations in manual compactor design focus on enhancing efficiency, portability, and user experience. Modern designs incorporate lightweight yet durable materials, such as advanced alloys and reinforced plastics, to improve maneuverability. Compact, foldable frames are gaining popularity, allowing for easy storage and transport. Additionally, ergonomic handles and adjustable grips reduce operator fatigue. Innovations also include modular components that can be customized for specific tasks, such as interchangeable pressing plates for different material types. Smart designs now integrate safety features like automatic locking mechanisms and anti-vibration systems, ensuring safer operation. These advancements are reshaping manual compactors into versatile, user-friendly tools for diverse applications.

10.2 Integration with Smart Technology

Manual compactors are increasingly integrating smart technology to enhance performance and efficiency. Sensors now monitor compaction force, cycle counts, and maintenance needs in real time. Bluetooth connectivity allows data tracking via mobile apps, enabling users to optimize operations and schedule maintenance. Automatic alerts notify operators when compaction levels are reached or when servicing is required. Some models feature energy-efficient motors that adjust power based on load, reducing energy consumption. Smart systems also enable remote troubleshooting, minimizing downtime. These innovations make manual compactors more versatile, user-friendly, and aligned with modern industrial demands, ensuring they remain essential tools in various industries.

10.3 Expected Growth in Market Demand

The demand for manual compactors is projected to grow significantly due to increasing waste management needs and environmental regulations. Urbanization and construction expansion drive the requirement for efficient waste compression solutions. industries like agriculture, landscaping, and small-scale recycling are adopting manual compactors for their versatility and cost-effectiveness. Additionally, rising awareness of sustainable practices fuels the adoption of compactors that reduce waste volume and enhance resource utilization. As governments implement stricter waste management protocols, the market for manual compactors is expected to expand further, offering affordable and eco-friendly alternatives to traditional methods. This growth underscores their essential role in modern waste management systems globally.